Without a doubt, 2D & 3D modeling software is one of the most important tool in your product design and development tool kit. So, it becomes imperative to stay up to date on the latest developments in this technology to become continuously faster and better with your product development process. This blog lists down the latest 2020 updates in the leading CAD packages such as SolidWorks, Solid Edge, Inventor, NX, Creo and Catia and discusses how these new features can help improving productivity and efficiency in your product development process.

Common Updates

Let's start with reviewing the updates which are common across all CAD platforms primarily been driven from today’s Industry requirements.

- Augmented Reality (AR):

It is a technology that enables us to interact with virtual models in real life. With AR, there is no need to guess or imagine how the product will look in different real-life places. A 3D object can be superimposed in real-life places to see the aesthetic appeal of the product, ensuring sizing relative to other objects, etc.

- Cloud Capabilities:

Local workstations have limitations in terms of performance due to hardware, space, cost, etc. Cloud computing is the way to overcome those limitations. The tasks that require high specifications hardware can be assigned to a remote server which will perform the task and the results can be seen on the local workstation. Cloud capabilities also include storing of files so that they can be accessed anywhere and anytime required. In 2019, most of the CAD packages started to offer Cloud services and in 2020 it has become a norm. Cloud-based CAD & simulation has reduced the design cycle time due to its speed and accuracy.

- Model Based Definitions (MBD):

MBD has been around for quite a while and it has recently started to gain popularity within enterprises. In the latest update, all the CAD packages have focused on improving and simplifying MBD so it can be easily implemented and used.

- Interoperability:

With collaborations from multiple organizations to enterprises, it became evident that working with the data from multiple sources required a needless hassle of conversions. Interoperability means working with different data without the need for conversion. In 2020, all the major CAD packages have improved interoperability to work with data from other CAD packages.

SolidWorks

SolidWorks is the leading middle-range CAD package which offers CAD, CAM & CAE. Since its inception in 1996, the main focus of SolidWorks is to simplify the modeling. SolidWorks 2020 will offer the following features that will help in designing.

- Flexible Components:

Assemblies can have rigid, moving as well as flexible components such as springs, ties, belts, cables, live hinges, etc. For showing various positions of flexible parts, number of configurations has to be created in individual parts. In SolidWorks 2020 parts can be assigned as flexible components. Flexible components will change their shape according to the assembly position. This feature reduces the time of creating configurations as well as processing power required for loading these configurations. It will help in visualize and validate parts and assembly quicker while reducing time and maintaining the Bill of Materials.

- STL Modification:

In our Reverse Engineering blog, we talked about different STL file modification processes. Of which, one of the process is convergent modeling offered by Siemens NX & Solid Edge. Similar to that, SolidWorks 2020 also incorporated Direct Mesh Editing to work directly with mesh models such as STL files. In this latest version, fillets, chamfers, holes and similar features can be added or removed directly from STL model.

- Additive Manufacturing:

SolidWorks 2020 includes a comprehensive list of 3D printers to generate a sliced model for 3D printers. With this, the model can be sliced without translating it into a tessellated geometry file such as STL or OBJ. Also, with 3DExperience marketplace designs can be uploaded to get a quote for 3D printing.

- 3DExperience Platform:

Dassault Systèmes announced its revolutionary platform 3DExperience in 2018. 3DExperience aimed to bring all of the Dassault's software under the one roof. It categorizes software into four types according to their functions: 3D modeling, Simulation, Social & Collaborative, and Information Intelligence. These are process-oriented and can be tailored to the need of organizations according to their industry.

Solid Age

Solid Edge is a middle-range CAD software of Siemens. It also offers limited CAM & CAE capabilities. It is famous for the Synchronous Technology but also offers traditional parametric modeling with a very short learning curve. With the release of Solid Edge 2020 with new features, it is a direct competitor for SolidWorks. Some of the new features in latest version are:

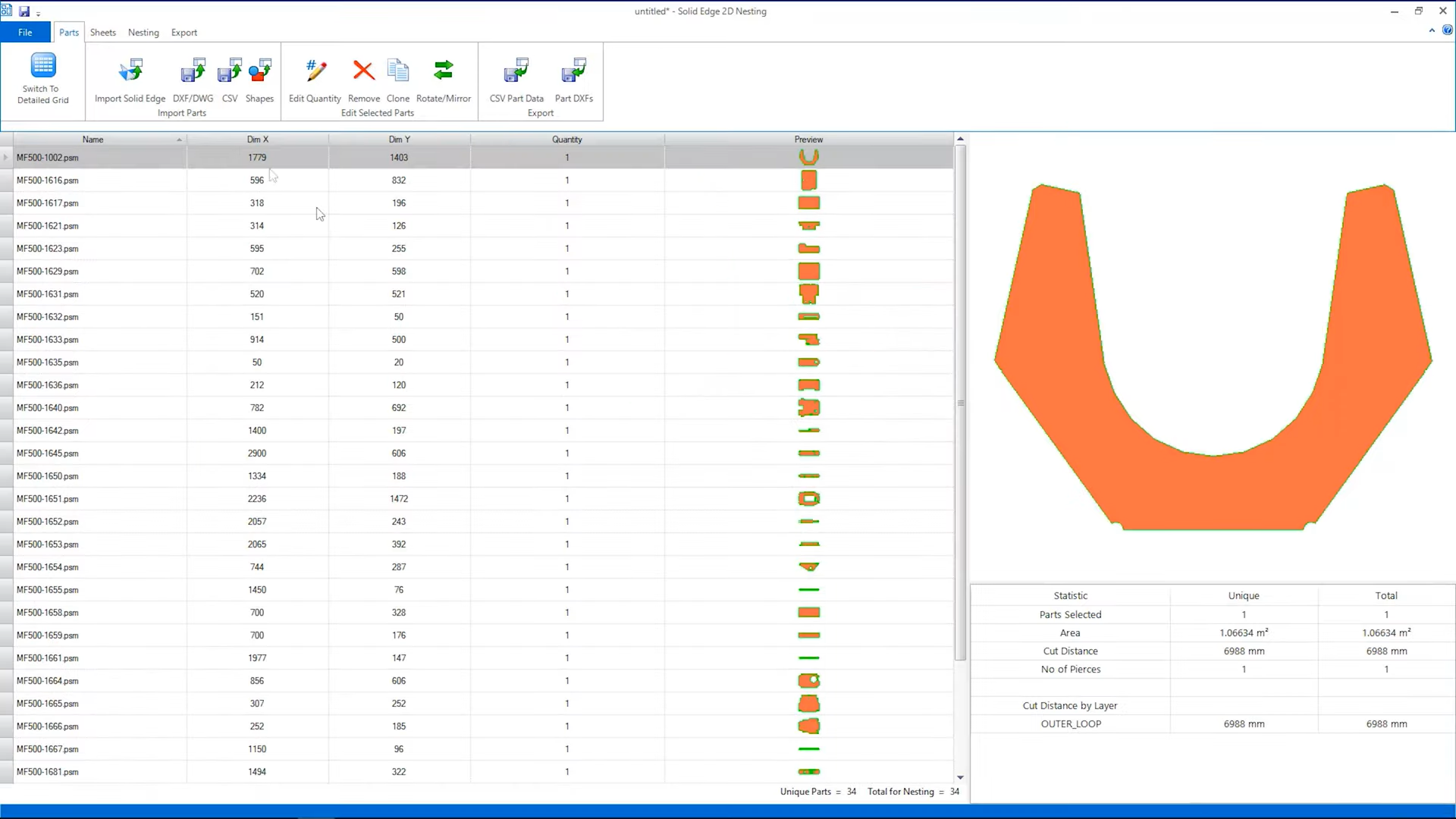

- Sheet Metal Design:

From the start, Solid Edge has offered a separate module for sheet metal designing and it is one of best out there to design sheet metal components. Solid Edge 2020 further enhanced this module with 2D Nesting feature to make optimized nesting of flat patterns on a sheet for cutting. It can be used for metal, plastic, and wood for CNC LASER cutting, shearing, or punching. Different sizes of sheets can be selected simultaneously for reducing waste and increasing utilization

- 3D Printing:

Solid Edge 2020 comes with in-built 3D printing features. With this, overhang can be analyzed and optimized part orientation can be found. Wall thickness analysis provides insights into areas that might be challenging to print due to wall thickness. Minimum wall thickness can be specified for analysis. The most challenging part in designing a 3D print is threading because the CAD software generally applies cosmetic threads to improve performance. But with the help of 'physical threads', this can be changed to actual threads. It also comes with the delete void option that can be used to remove internal voids for powder-based additive manufacturing.

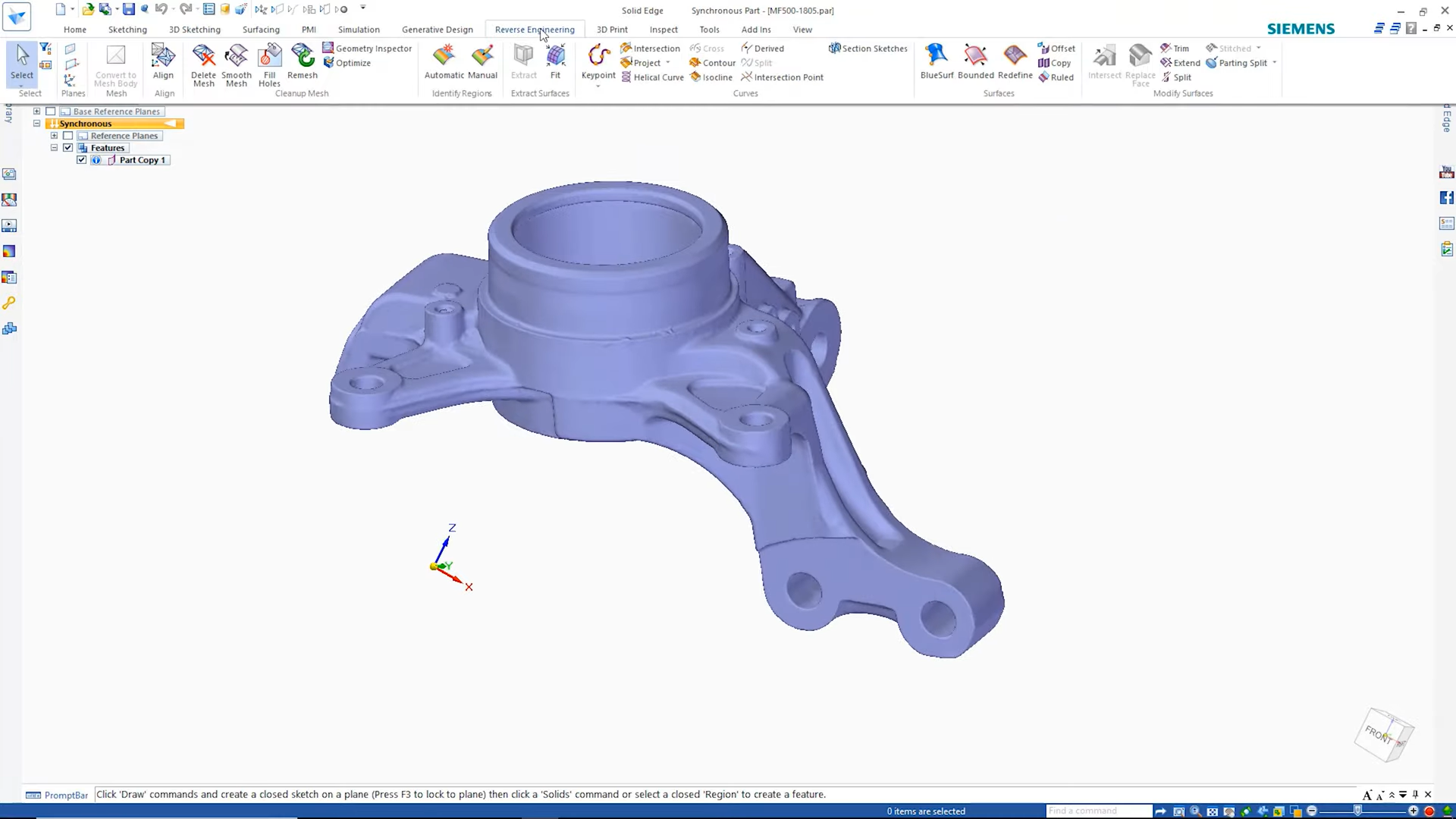

- Reverse Engineering:

Siemens introduced convergent modeling in both NX and Solid Edge to enhance its reverse engineering capabilities. Solid Edge 2020 has enhanced its meshed handling capabilities before starting the convergent modeling. New features include remeshing, redefining the origin of the model, identifying planer and cylindrical surfaces, adding sketches to different sections. After that convergent modeling can also be used to further modifications in the model. Scanned part can be directly added into the assembly and mates can be applied.

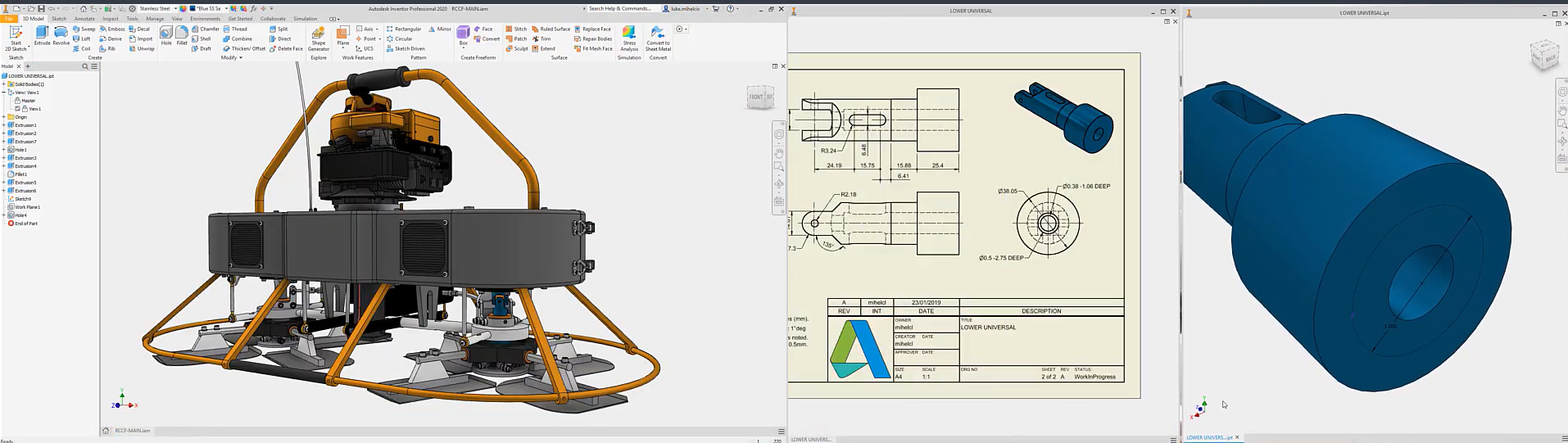

Inventor

Autodesk has been always remained one of the top technology providers for engineering industries. Besides AutoCAD which is the most common software used for 2D designing, Autodesk Inventor is a 3D CAD package with CAM & CAE capabilities. Inventor 2020 has the following new features:

- Unwrapped:

Flattening a sheet metal part is necessary for manufacturing. But sometimes the part may not be made in sheet metal cannot be flattened. For this Inventor 2020 introduces 'Unwrapped' command. It can be used to create a flat surface of any geometry having continuous surfaces.

- Sweep:

Sweep is a common CAD feature that is offered by all the CAD packages, but with Inventor 2020 a solid body can be swept around a path to create protrusions or cutouts.

- Multi-Monitor Support:

It is one of the most user centric enhancements in the year 2020. With multi-monitor support, you can work on multiple models simultaneously without switching the windows. It makes work easier when working on assembly and a sub-assembly or part so that any changes in the part file can be seen in assembly side by side.

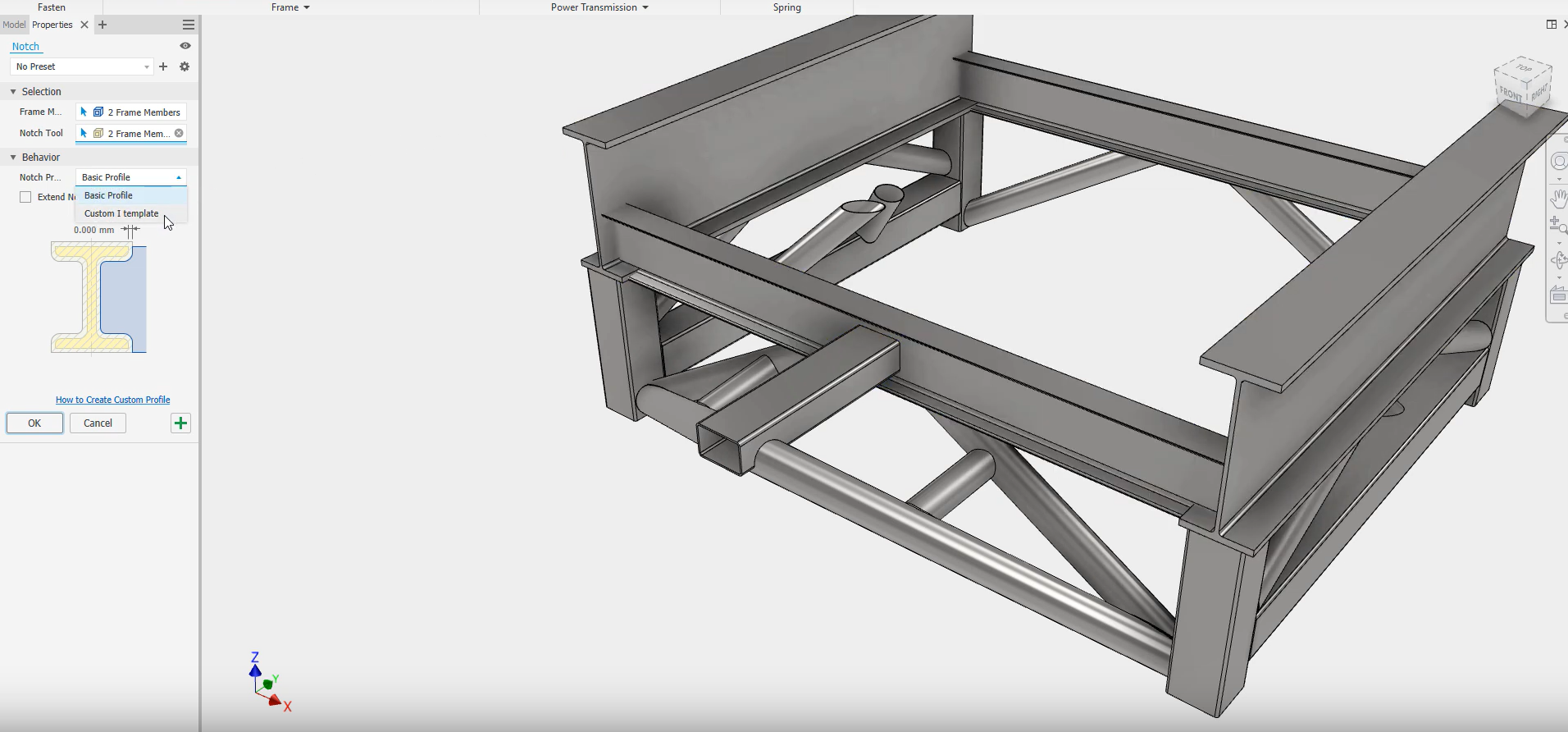

- Frame Generator:

Creating frames was always time consuming, but with improved features, it can be created quickly and accurately. It lets you create notches, and end-caps for frame members by just a few clicks and directly selecting the frame members. Custom end-caps can also be assigned to a frame member.

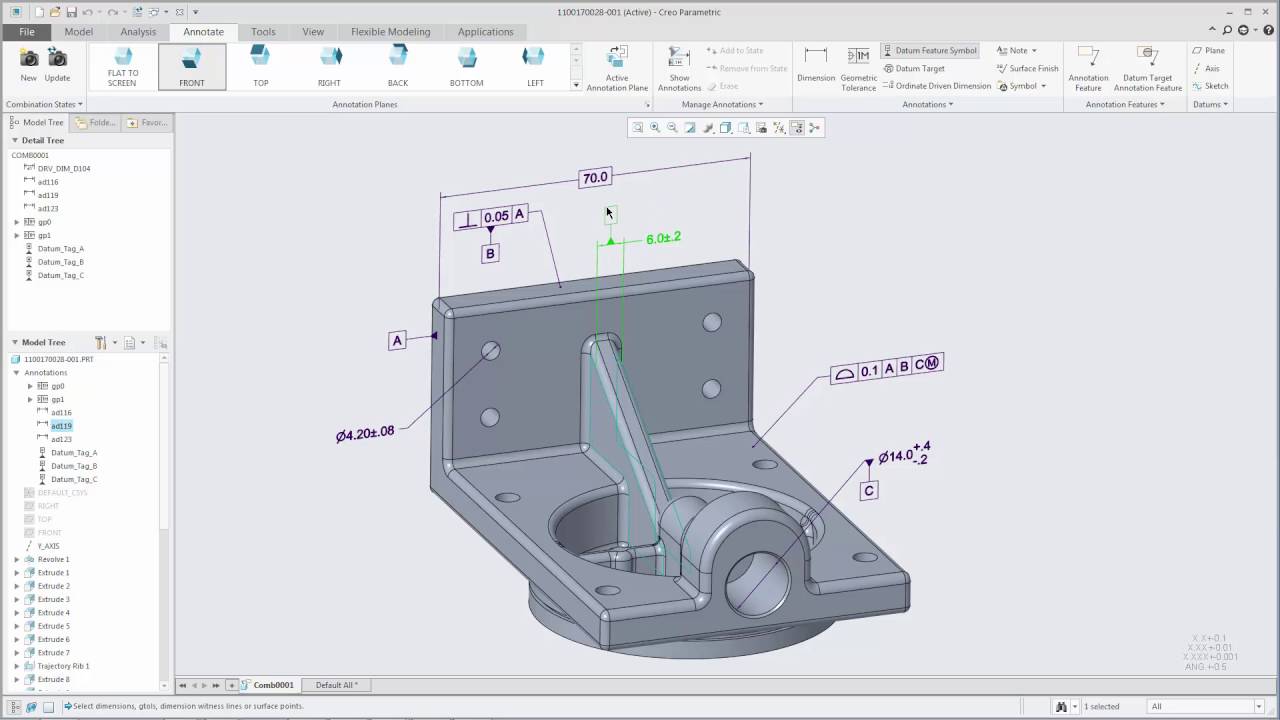

CREO

Creo is a high-end CAD, CAM & CAE package by PTC. It is a direct competitor of NX & CATIA. Creo 6.0 is the latest release by PTC. New features include:

- Simulation Live:

Simulation Live is a feature powered by Ansys which performs simulation in background in the CAD environment. Any changes in the model get reflected in the simulation study simultaneously. It gives instant feedback in real-time to any design changes. With these designers can create more robust products concurrently to speed up the design cycle.

- Additive Manufacturing:

Creo 6.0 has improved its lattice design for additive manufacturing. Formula driven lattice can be assigned using Creo Geometry. Build direction can be optimized to reduce print time, reduce support structures, maximize bed, or tray utilization and to drive the lattice design.

CATIA

CATIA is a high-end CAD, CAM & CAE package of Dassault System. Although SolidWorks is a more popular product, it has limited capabilities. CATIA has enhanced surfacing module which can be used to create Class A surfacing for automotive and aerospace.

NX

NX (formerly known as UG) is high-end CAD, CAM & CAE package by Siemens. Since NX is a high-end version it has all the features that Solid Edge has with some of the enhanced features. Starting from 2018 NX has four digit tracking no. for software updates under the continuous release.

Disclaimer: Limited information was available on NX and Catia about their recent updates. There is a good chance that more updates have been released besides what’s covered in this blog.

Improvians Take

All the CAD packages described above offers more than basic 3D modeling with some advanced features. The selection of the CAD should be based on the type of work required and the cost of the package. All the packages offer multiple combinations with limiting capabilities. More features will cost more money so unless it is necessary, there won’t be a need to buy high-end packages or premium versions. The first choice for selection should be between high-end and middle-range, then between different packages. The things that can be done on one of the middle range packages can be done on any other package. High-end software may specialize in certain areas such as surfacing in CATIA, CAM in NX, and mold design in Creo. At Improvians, we help you with end to end product designing and modeling requirements. Get in touch with us to know more about our process and capabilities.

- https://www.javelin-tech.com/blog/2019/09/solidworks-2020-whats-new-top-10/

- https://solidedge.siemens.com/en/solutions/products/complete-product-development-portfolio/whats-new-in-solid-edge-2020/

- https://www.plm.automation.siemens.com/global/en/products/nx/

- https://www.3ds.com/products-services/catia/products/3dexperience/whats-new/tag/new/

- https://www.autodesk.in/products/inventor/new-features

- https://www.ptc.com/en/products/cad/creo/whats-new