Mechanical Product Development

Develop 2D and 3D Designs for Manufacturing.

“Design at speed and scale.”

Design and develop cutting-edge products at speed and scale by partnering with our experienced mechanical engineering team.

Improvians can take on end-to-end product development or join in as your extended team at any stage of the product lifecycle.

How Our Experience Mechanical Engineers Can Help

New Product Design

-

User Market Research

-

Sketching/Ideation

-

Industrial Design

-

Computer Aided Design (CAD)

-

Sheet Metal Design

-

Plastic Part Design

-

Weldment Design

-

Surface Modelling

-

Mechanism Design

New Product Development

-

Engineering Design Detailing

-

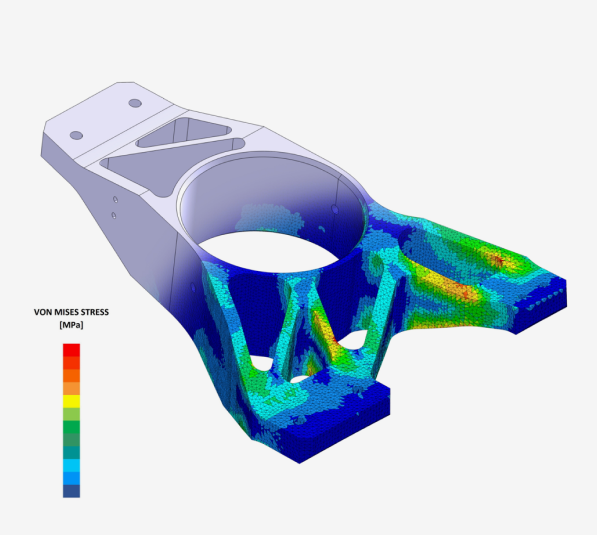

Finite Element Analysis

-

Kinematic and Motion Analysis

-

Prototype and Testing

-

Tolerance Analysis

-

Design for Manufacturing

-

Design for Assembly

-

Iterative Development

-

Manufacturing Drawings

Manufacturing Engineering

-

CAM Programming

-

Jigs and Fixture Design

-

Tooling Selection

-

Manufacturing Drawings

-

Controls Documentation

-

Design Revisions

-

Legacy Product Management

Design for Manufacturing

We understand manufacturing processes and create designs as per it.

CNC Machining

3D Printing

Laser Cutting

Waterjet Cutting

Sheet Metal

Injection Molding

Our Expertise

Proof of Concept

Design

We initiate by brainstorming and ideating to conceive new product concepts, defining their purpose, features, and problem-solving capabilities. We meticulously plan the design process, setting goals, specifying requirements, and outlining project scope.

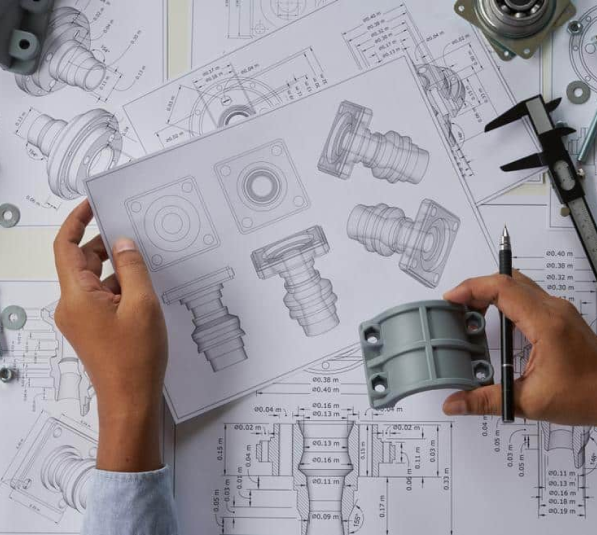

Sketching and CAD Modeling

Visualizing the product's appearance and layout is vital. Initial sketches and drawings, whether done by hand or using CAD software, help us grasp the design's aesthetics. CAD software enables us to create precise three-dimensional models, ensuring a detailed understanding of the design and its components.

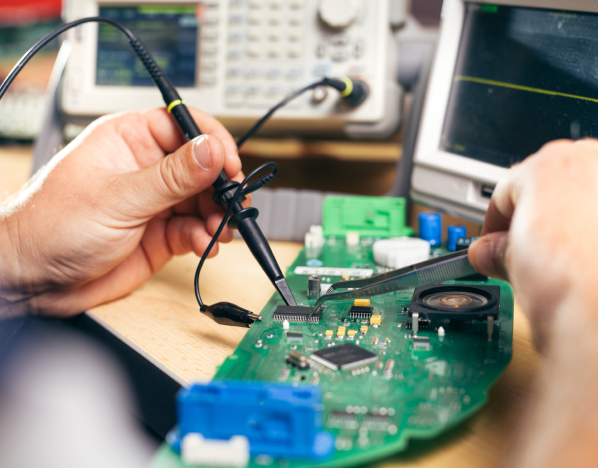

Analysis, Simulation, and Testing

To ensure product integrity, we conduct various simulations and analyses on the digital model, identifying and addressing issues before manufacturing. After prototyping, rigorous testing validates quality standards, functional performance, and safety compliance.

Component Bill of Material

Material selection is a crucial step. We choose materials tailored to the product's performance, durability, and cost-efficiency, considering specific functions and environments. Simultaneously, we create a dynamic Bill of Materials (BOM), listing components, both off-the-shelf and custom-designed, to be used in the product's assembly.

Design for Manufacturability

The design is refined by incorporating all components, considering ergonomics, and ensuring seamless functionality. Concurrently, we focus on manufacturability, designing parts for easy production, assembly, and maintenance for diverse manufacturing processes such as plastics, sheet metal, machined parts, weldments, etc.

Documentation and Finalization

Comprehensive documentation is created, including manufacturing detailed drawings, specifications, and assembly instructions, serving as a guide for precise production and assembly. Geometric dimensional and tolerances (GD&T) are defined and reviewed with the manufacturing supplier.

Continuous Design Improvement

Design is iterative. We continually improve and adjust it based on testing outcomes, user feedback, and real-world performance data. Through each iteration, we strive for innovation, ensuring our designs evolve to meet the dynamic needs of our users and the demands of the ever-changing landscape.

Packaging and Presentation

Crafting an appealing product presentation, including packaging, is essential for attracting customers and ensuring the product reaches them securely, complementing our comprehensive product development strategy.

Manufacturing

Support

We help you find the right vendor for your product manufacturing and setup production process. This includes developing quality management systems, implementation of inspections and testing protocols, use of statistical process control techniques to monitor and maintain product quality throughout the manufacturing process.

Why Choose Improvians?

Domain Expert

Dedicated Resources

Timely Response

Increased Profit

Zero Risk Working

Total Team Flexibility

Other Services

Have a Project to Discuss?

Contact us for free consultation.